As Bay-Lynx prepares for our 5th exhibit at the annual World of Concrete show, we are thrilled to be, once again, at the Las Vegas Convention Center taking place on January 17 – 19. World of Concrete is the commercial construction industry’s largest annual convention for concrete and masonry professionals. More than 60,000 industry experts from all segments of the business will gather to view cutting-edge equipment, tools, and services. Representatives from Bay-Lynx will be on hand to discuss the advantages of using its state-of-the-art volumetric mixers.

At our booth, we will be displaying a couple of the Bay-Lynx Titan mixers and will have a team of experts present to answer all your questions and determine how Bay-Lynx’s products could enhance your project. We’ll explore the best options for you, we’ll discuss the necessary customizations to achieve the best results, and we’ll ensure you have all the information you need. Also see the BatchPro Connect first hand with demonstrations and walk-throughs.

Be sure to visit Bay-Lynx at C4011 in the Las Vegas Convention Center’s Central Hall. To learn more about us, visit bay-lynx.com. And, to learn more about this year’s World of Concrete Convention and plan your trip, visit worldofconcrete.com.

As Bay-Lynx prepares for our 5th exhibit at the annual World of Concrete show, we are thrilled to be, once again, at the Las Vegas Convention Center taking place on January 17 – 19. World of Concrete is the commercial construction industry’s largest annual convention for concrete and masonry professionals. More than 60,000 industry experts from all segments of the business will gather to view cutting-edge equipment, tools, and services. Representatives from Bay-Lynx will be on hand to discuss the advantages of using its state-of-the-art volumetric mixers.

At our booth, we will be displaying a couple of the Bay-Lynx Titan mixers and will have a team of experts present to answer all your questions and determine how Bay-Lynx’s products could enhance your project. We’ll explore the best options for you, we’ll discuss the necessary customizations to achieve the best results, and we’ll ensure you have all the information you need. Also see the BatchPro Connect first hand with demonstrations and walk-throughs.

Be sure to visit Bay-Lynx at C4011 in the Las Vegas Convention Center’s Central Hall. To learn more about us, visit bay-lynx.com. And, to learn more about this year’s World of Concrete Convention and plan your trip, visit worldofconcrete.com.

On April 13, 2022, we welcomed a variety of volumetric mixer owners and operators to the 2022 Concrete Academy Day. After a 2 year hiatus from the otherwise annual event, we were finally able to open our doors back to the training/certification program so many of our customers have been asking for. Concrete Academy Day is traditionally a training event on concrete technology as it relates to volumetric mixers. However, this year we conducted the VMOC (Volumetric Mixer Operator Certification) program from the VMMB.

The day featured topics such as safety, concrete technology, concrete components and their use, volumetric mixer operations and components, and customer relations. After the day of classes, many operators chose to take the VMOC exam as well to label themselves as official certified volumetric mixer operators.

Bay-Lynx would like to thank all those who attended as we push to make the volumetric mixer operators some of the most qualified members of the concrete industry.

On April 13, 2022, we welcomed a variety of volumetric mixer owners and operators to the 2022 Concrete Academy Day. After a 2 year hiatus from the otherwise annual event, we were finally able to open our doors back to the training/certification program so many of our customers have been asking for. Concrete Academy Day is traditionally a training event on concrete technology as it relates to volumetric mixers. However, this year we conducted the VMOC (Volumetric Mixer Operator Certification) program from the VMMB.

The day featured topics such as safety, concrete technology, concrete components and their use, volumetric mixer operations and components, and customer relations. After the day of classes, many operators chose to take the VMOC exam as well to label themselves as official certified volumetric mixer operators.

Bay-Lynx would like to thank all those who attended as we push to make the volumetric mixer operators some of the most qualified members of the concrete industry.

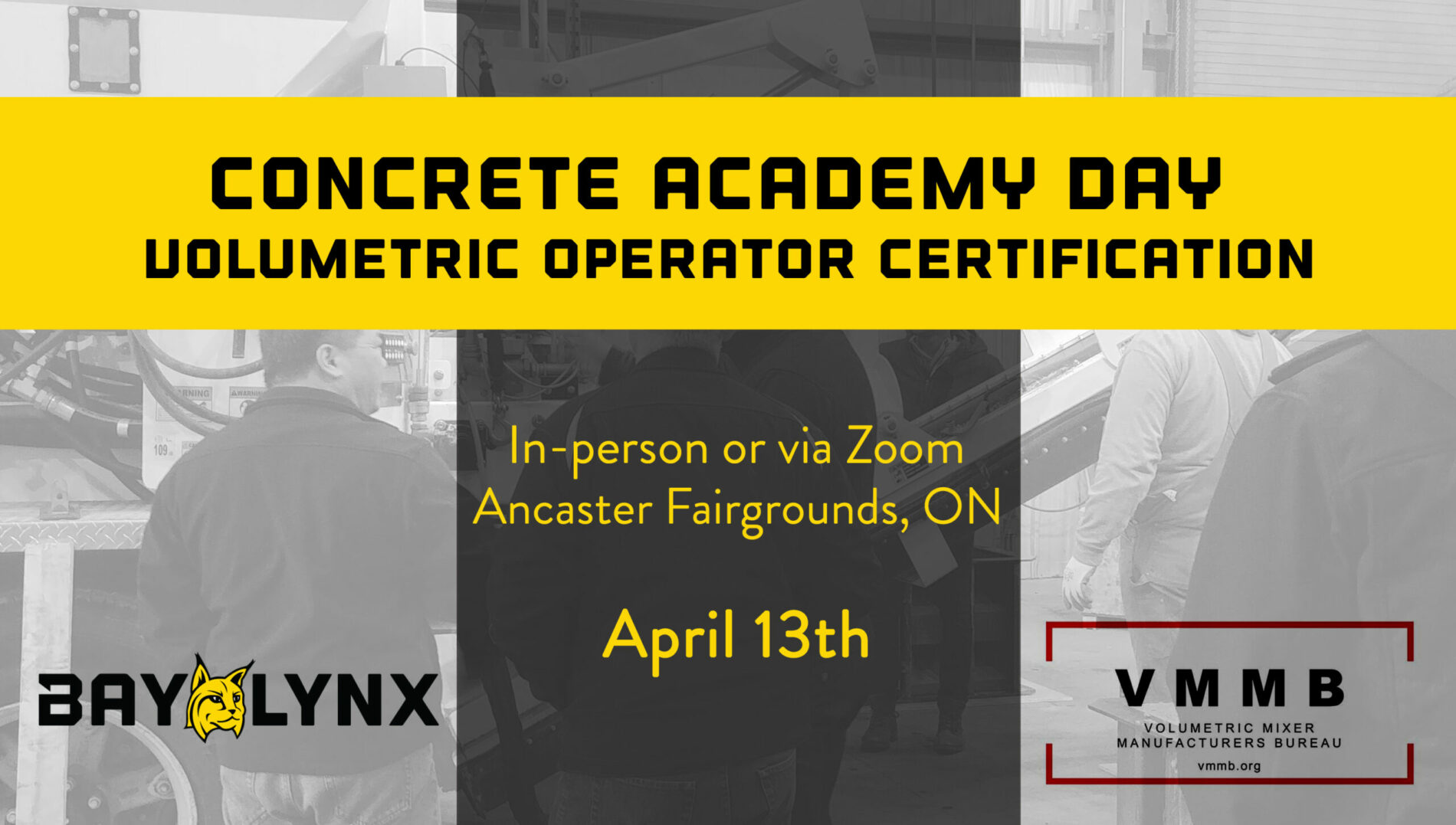

Bay-Lynx is pleased to announce we will be hosting our annual Volumetric Concrete Academy Day on April 13th!

This year we will be offering Volumetric Mixer Operator Certification training and examination through the VVMB’s VMOC program. We’ll cover everything from concrete technology to customer relations. Following the course, you may participate in the exam to gain your volumetric mixer operator certification. Whether you are an operator looking to be certified, an owner or just in the concrete industry and would like to learn more about the volumetric industry, this is a great opportunity!

The course dives into the fundamentals of concrete, its different components, concrete admixtures, and concrete testing. You’ll than learn about operating a volumetric mixer, the components and controls of the machine, calibration, plant and job-site operations and related environmental issues. We’ll also cover the personal and job-site safety hazards involved in operating a mixer and any precautions that must be taken. Lastly, we’ll go through customer and company relations where you’ll learn the basics of customer service, dealing with customer issues and dealing with your company and fellow employees.

Classes are free to attend for educational purposes, but certification will cost $300 USD. Classes will be hosted at the Ancaster Fairgrounds, with the option to join via Zoom. Contact our sales team today to register for this year’s Concrete Academy!

Bay-Lynx is pleased to announce we will be hosting our annual Volumetric Concrete Academy Day on April 13th!

This year we will be offering Volumetric Mixer Operator Certification training and examination through the VVMB’s VMOC program. We’ll cover everything from concrete technology to customer relations. Following the course, you may participate in the exam to gain your volumetric mixer operator certification. Whether you are an operator looking to be certified, an owner or just in the concrete industry and would like to learn more about the volumetric industry, this is a great opportunity!

The course dives into the fundamentals of concrete, its different components, concrete admixtures, and concrete testing. You’ll than learn about operating a volumetric mixer, the components and controls of the machine, calibration, plant and job-site operations and related environmental issues. We’ll also cover the personal and job-site safety hazards involved in operating a mixer and any precautions that must be taken. Lastly, we’ll go through customer and company relations where you’ll learn the basics of customer service, dealing with customer issues and dealing with your company and fellow employees.

Classes are free to attend for educational purposes, but certification will cost $300 USD. Classes will be hosted at the Ancaster Fairgrounds, with the option to join via Zoom. Contact our sales team today to register for this year’s Concrete Academy!

Bay-Lynx was honored to once again be a part of the highly anticipated World of Concrete show, January 16-19 at the Las Vegas Convention Center. Our salesmen were pleased to meet with the crowds of prospective buyers and showcase our quality products.

Bay-Lynx was excited to proudly display the Titan volumetric mixer once again. The Titan has just celebrated its two-year anniversary, but the buzz about this new mixer hasn’t settled. With its incredible durability, light weight and long lifespan, the Titan remains quite a highlight in the concrete world!

The Hardox 450 steel’s flexible build removes unnecessary weight and maximizes payloads, accounting for over 1,350 lbs. of weight savings. Lighter components mean fuel savings, increased capacity and reduced environmental impact.

The Hardox 450 steel is some of the strongest and toughest steel in the world, able to withstand any material that operators load it up with. The hardness of the steel provides better dent scratch resistance, avoiding rust and keeping your fleet in like-new condition. As a result, this has increased the Titan’s service life to over 200% compared to that of a standard mixer.

Not only have payload and durability increased, but the resale values of construction equipment made with Hardox steel are 15% higher than their mild steel counterparts.

The Titan mixer also includes some of the most advanced mixing technology on the market. The new BatchPro 3.0 Panel and automation components on the mixer communicate with the BatchPro Connect App to control all sand, stone, cement, water and admixture contents.

BatchPro Connect is a three-tiered software solution that includes a customer order portal, a dispatch platform and an operator’s mobile application. The customer order portal can be linked to your website to allow customers to place an order online, which can then be sent directly to dispatch. The dispatch platform communicates to the mixers through the operator’s mobile application. It creates jobs and assigns them to your mixers, allowing you to track all jobs with digital copies of the tickets and receive status notifications from your operators. The operator’s mobile application simplifies all day-to-day tasks of concrete delivery. This application allows you to print tickets, collect signatures and get a faster and more accurate mixer calibration. This BatchPro Connect technology will save you time and money, while providing an exceptional customer experience!

Bay-Lynx’s complete line of innovative products, including the Titan, BatchPro Connect and Ultralite Plus are changing how the world looks at concrete delivery.

Take the next step and learn why thousands of people around the world choose Bay-Lynx. Give us a shout. We would love to learn more about your goals and plans to provide a customized machine right for you.

Bay-Lynx was honored to once again be a part of the highly anticipated World of Concrete show, January 16-19 at the Las Vegas Convention Center. Our salesmen were pleased to meet with the crowds of prospective buyers and showcase our quality products.

Bay-Lynx was excited to proudly display the Titan volumetric mixer once again. The Titan has just celebrated its two-year anniversary, but the buzz about this new mixer hasn’t settled. With its incredible durability, light weight and long lifespan, the Titan remains quite a highlight in the concrete world!

The Hardox 450 steel’s flexible build removes unnecessary weight and maximizes payloads, accounting for over 1,350 lbs. of weight savings. Lighter components mean fuel savings, increased capacity and reduced environmental impact.

The Hardox 450 steel is some of the strongest and toughest steel in the world, able to withstand any material that operators load it up with. The hardness of the steel provides better dent scratch resistance, avoiding rust and keeping your fleet in like-new condition. As a result, this has increased the Titan’s service life to over 200% compared to that of a standard mixer.

Not only have payload and durability increased, but the resale values of construction equipment made with Hardox steel are 15% higher than their mild steel counterparts.

The Titan mixer also includes some of the most advanced mixing technology on the market. The new BatchPro 3.0 Panel and automation components on the mixer communicate with the BatchPro Connect App to control all sand, stone, cement, water and admixture contents.

BatchPro Connect is a three-tiered software solution that includes a customer order portal, a dispatch platform and an operator’s mobile application. The customer order portal can be linked to your website to allow customers to place an order online, which can then be sent directly to dispatch. The dispatch platform communicates to the mixers through the operator’s mobile application. It creates jobs and assigns them to your mixers, allowing you to track all jobs with digital copies of the tickets and receive status notifications from your operators. The operator’s mobile application simplifies all day-to-day tasks of concrete delivery. This application allows you to print tickets, collect signatures and get a faster and more accurate mixer calibration. This BatchPro Connect technology will save you time and money, while providing an exceptional customer experience!

Bay-Lynx’s complete line of innovative products, including the Titan, BatchPro Connect and Ultralite Plus are changing how the world looks at concrete delivery.

Take the next step and learn why thousands of people around the world choose Bay-Lynx. Give us a shout. We would love to learn more about your goals and plans to provide a customized machine right for you.

The annual concrete and masonry convention takes place January 18-20 in Las Vegas

Bay-Lynx is excited to once again be a part of the annual World of Concrete show, taking place on January 18-20 at the Las Vegas Convention Center. World of Concrete is the commercial construction industry’s largest annual convention for concrete and masonry professionals. During the event, more than 60,000 industry experts from all segments of the business will gather to view cutting-edge equipment, tools, and services. Representatives from Bay-Lynx will be on hand to discuss the advantages of using its state-of-the-art products.

Since 1992, Bay-Lynx has manufactured high-quality equipment for construction companies, including volumetric concrete mixers, stone spreaders, and cambering machines. Among the many benefits of working with Bay-Lynx, we customize our equipment for each client’s needs and every product is built for a long shelf life.

When you visit the Bay-Lynx booth, expect detailed presentations, examples, and case studies of our great products:

Titan Volumetric Mixer: The Titan Mixer features Hardox steel, the strongest and toughest steel in the world! This steel is known for its incredible strength and flexible build, enabling workers to maximize payload. Hardox steel also resists denting, puncturing, and scuffing, resulting in a much longer service life. Not only is the Titan lighter and stronger, its also smarter! The Titan Mixer features the BatchPro 3.0 operator’s panel, which works seamlessly with the BatchPro Connect app and enables direct communication between a designated mobile device and the mixer. The Titan is also completely automated, removing the guesswork from crucial mixing steps like water dosage and gate settings.

BatchPro Connect: This is our three-tiered software solution for concrete producers. BatchPro Connect goes much further than the standard construction app and addresses customers, dispatchers, and operators. Every step of the process can be handled in-app, from ordering to pouring to recording. During your booth visit, get hands on and explore BatchPro Connect’s many functions.

At our booth, we’ll have a team of experts present to answer all your questions and determine how Bay-Lynx’s products could enhance your project. We’ll explore the best options for you, we’ll discuss the necessary customizations to achieve the best results, and we’ll ensure you have all the information you need.

Be sure to visit Bay-Lynx at W2531 in the Las Vegas Convention Centre’s West Hall. To learn more about us, visit bay-lynx.com. And, to learn more about this year’s World of Concrete convention and plan your trip, visit worldofconcrete.com.

The annual concrete and masonry convention takes place January 18-20 in Las Vegas

Bay-Lynx is excited to once again be a part of the annual World of Concrete show, taking place on January 18-20 at the Las Vegas Convention Center. World of Concrete is the commercial construction industry’s largest annual convention for concrete and masonry professionals. During the event, more than 60,000 industry experts from all segments of the business will gather to view cutting-edge equipment, tools, and services. Representatives from Bay-Lynx will be on hand to discuss the advantages of using its state-of-the-art products.

Since 1992, Bay-Lynx has manufactured high-quality equipment for construction companies, including volumetric concrete mixers, stone spreaders, and cambering machines. Among the many benefits of working with Bay-Lynx, we customize our equipment for each client’s needs and every product is built for a long shelf life.

When you visit the Bay-Lynx booth, expect detailed presentations, examples, and case studies of our great products:

Titan Volumetric Mixer: The Titan Mixer features Hardox steel, the strongest and toughest steel in the world! This steel is known for its incredible strength and flexible build, enabling workers to maximize payload. Hardox steel also resists denting, puncturing, and scuffing, resulting in a much longer service life. Not only is the Titan lighter and stronger, its also smarter! The Titan Mixer features the BatchPro 3.0 operator’s panel, which works seamlessly with the BatchPro Connect app and enables direct communication between a designated mobile device and the mixer. The Titan is also completely automated, removing the guesswork from crucial mixing steps like water dosage and gate settings.

BatchPro Connect: This is our three-tiered software solution for concrete producers. BatchPro Connect goes much further than the standard construction app and addresses customers, dispatchers, and operators. Every step of the process can be handled in-app, from ordering to pouring to recording. During your booth visit, get hands on and explore BatchPro Connect’s many functions.

At our booth, we’ll have a team of experts present to answer all your questions and determine how Bay-Lynx’s products could enhance your project. We’ll explore the best options for you, we’ll discuss the necessary customizations to achieve the best results, and we’ll ensure you have all the information you need.

Be sure to visit Bay-Lynx at W2531 in the Las Vegas Convention Centre’s West Hall. To learn more about us, visit bay-lynx.com. And, to learn more about this year’s World of Concrete convention and plan your trip, visit worldofconcrete.com.