Concrete is made up of 4 keys ingredients: cementitious material, fine aggregates, coarse aggregates, and water. While each of these materials plays a certain role in the concrete, the water is the ingredient that starts the whole chemical reaction. Water and cement are combined to create the binder (cement paste) and the aggregates are used as the filler. As water is added to cement it creates a paste that glues all of the aggregates together. The cement paste then undergoes a chemical process known as hydration, this chemical reaction is what allows the concrete to harden and become strong and solid.

Water has a very important role in concrete if too much water is added to the mix it will reduce the final strength of the concrete, however, if too little water is added the concrete will be unworkable and will not allow workers to finish it properly. Water makes up about 15%-18% of the total concrete volume, too much water reduces strength and durability, increases set times and shrinkage, and weakens the surface of the concrete by causing dusting or flaking.

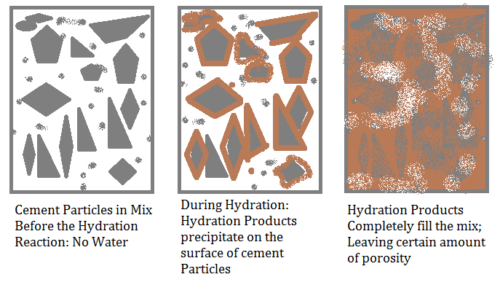

Another variable that can affect the strength of the concrete is the purity of the water. The more contaminated the water is the more side reactions will occur which may weaken the concrete or interfere with the main hydration reactions. As hydration reactions occur a network of crystal-like formations grow throughout the concrete. This reaction is what give the final product its strength once the concrete is cured. While most of the concretes strength is gained with in the first 28 days, the concrete will continue to strengthen as long as there is un-hydrated cement with access to moisture. The image below shows the crystal like formations forming through the concrete during the hydration process.

Water reducers are very popular in concrete, they allow the concrete to remain highly workable without adding excess water to the mix. This is a big benefit to concrete workers because it allows them more time to properly finish the concrete without adding excess water. It is estimated that 70% to possibly even 90% of current concrete has water reducers added to it. Less water also helps with bleeding, by reducing the amount of water in the concrete mix workers can eliminate excess water bleed which can cause flaking on the surface of the finished concrete.

Many people agree that there is no downside to using water reducers as long as they are used properly. One mistake that people can make is the overuse of retarding admixtures. When retarders are overused in windy environments, it can cause the surface of the concrete to cure faster than the base which is known as “plastic shrinkage cracking”. As long as there is proper communication between the suppliers and workers this problem can be avoided.

As previously mentioned in this article, there are 2 main ways in which water can decrease the overall strength of the concrete. These two ways are over watering and using contaminated water. Salt has a huge impact on the final strength of the concrete, sea water has an average of 3.5% salt composition and is made of the same chemical composition throughout the world. With the chemical makeup of sea water the cured concrete can have a reduced strength of 10%-20%. This however, is not the only thing that is affected by impure water; if the the water has chlorides in it they will corrode the steel reinforcements that are set inside the concrete.

When too much water is added to the concrete mixture not all of the water will be used in the hydration reaction. The extra water in the mixture will then evaporate out of the concrete mixture and leave voids inside the cured mix. These voids than contribute to the loss of the final compressive strength of the concrete. In fact, for every additional 10 liters of water per cubic meter of concrete, the end result will be 2.5 MPa (365 PSI) less compressive strength.

Adding too much water can have multiple negative side effects including:

Using volumetric mixers is beneficial in many ways. One way they can be beneficial is that the concrete is not mixed until it is needed, when concrete is mixed for prolonged periods of time it can become stiff and harder to work with. This can make it tempting to add water to the mix to prolong workability time which will then decrease the strength and overall quality of the concrete. Another benefit to volumetric mixers is that the water can be adjusted on the fly to ensure that the proper water to cement ratio is always being achieved through out the entire pour.

Water is a very important part of concrete it has a direct impact on the strength and quality. Special attention must be paid to how much water and how pure the water is that is used in the concrete mixture.